Industrial coating. Precise, fast & scalable.

We coat steel, aluminium and stainless steel. With 5 systems (3 manual booths, 2 fully automated lines) and our own fleet, we're usually done in 3 business days – even for parts up to 6 meters.

Figures & facts

Planning certainty at a glance.

Materials

Steel, aluminium, stainless steel

We coat parts up to 2.0 x 2.3 x 6.0 m; in automated lines also overlengths up to 6 m.

Services

From pretreatment to final inspection.

Pretreatment, coating and logistics from one source. It saves coordination and time and keeps your parts moving.

Powder coating

Modern systems for parts up to 2.0 x 2.3 x 6.0 m, fast turnaround and many colors.

Corrosion protection & pretreatment

Passivation and phosphating for steel, aluminium and zinc. Optional thick-film passivation with SurTec.

Thick-film passivation with SurTec

High-quality corrosion protection for demanding applications and longer service life.

Assembly & logistics

Assembly of coated parts up to the finished product.

Process

Plannable, repeatable, measurable.

We work with clear process windows and document every batch – so you get consistent quality and approvals run smoothly.

Step 01

Passivation & phosphating

Pretreatment for various materials, including thick-film passivation with SurTec.

Step 02

Powder coating

Small parts, components and series in changing colors with short lead times.

Step 03

Assembly & logistics

Assembly up to the finished product and our own fleet with 2 trucks.

Industries

Coating for demanding applications.

Whether protection, appearance or function: we find the right coating system for your parts.

Suppliers

Strong partners for powder coatings and pretreatment.

We rely on manufacturers we have known for years. This keeps quality and lead times stable.

Close cooperation ensures quick availability and reliable processes – even when things are urgent.

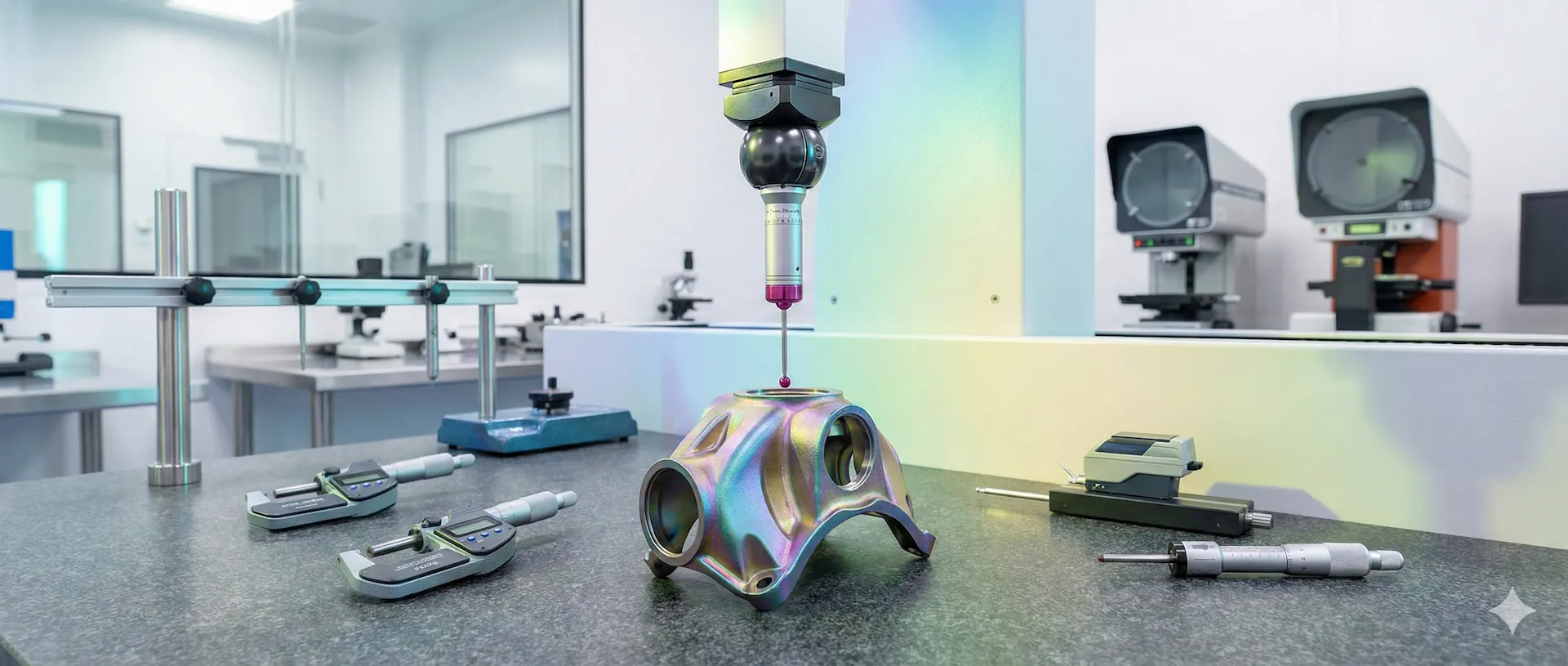

Quality you can measure.

Requirements from the automotive industry have shaped our standards – all sectors benefit.

Process reliability

Approvals move fast, results stay reproducible.

Corrosion protection

Passivation and phosphating for strong adhesion and long service life.

Appearance & feel

Many colors, textures and special shades.

Customer satisfaction

Voices from everyday work.

Fast response times, clean quality and reliable processes – that's what our customers rely on.

Top quality and a unique service. Here the customer is still treated like a customer. Simply great and gladly again.

MHMarcel de Haer

Competent advice, fast and clean work. Price-wise unbeatable. I'd gladly come again.

SBSascha Blöß

Picked up my railing today and, as always, very satisfied with the quality. Clean work, great quality and good customer service – that's how it should be. Many thanks WESA-dress.

AGAndreas Gradziski

I can warmly recommend this professional company to everyone. The collaboration is first-class. Good quality and friendly service.

ECEKO-COLOR

Customers

Trust that lasts.

For years we have supported customers in industry, metal construction and series production.

We see ourselves not only as a service provider, but as an extended workbench for your company. Many customers have been with us for years – because they know they can rely on our word and our quality.

Contact

Just send us a short message – we usually reply the same business day.

We will prepare a fair quote and advise which corrosion protection best fits your use case.

FAQ

Short and clear answers.

Lead times, services and production capabilities at a glance.

How fast is the turnaround time?

Usually 2 to 4 business days, often 3. If it's urgent, just let us know – we often find a solution.

What part sizes can be coated?

We process parts up to 2.0 x 2.3 x 6.0 m. In the fully automated lines, parts up to 6 m are possible.

Which services does WESA-dress offer?

We powder coat, passivate/phosphate and, on request, handle assembly and logistics – all from one source.

When can you reach us?

Mon–Fri 06:00 to 14:30. Feel free to write us via the contact form.

Do you pick up and deliver back?

Yes. With our own fleet we can pick up your parts and deliver them back finished. Just ask us about a route.